Table of Contents

Thickness planers are a type of machine that can be used to plane wood and other materials. They are often used in carpentry or construction, but they can also be useful for those who use them at home. If you’re just getting started with thickness planers, this article will help you learn what they are and how they work. We’ll also give you some tips on what to look out for when using one!

What is a thickness planer?

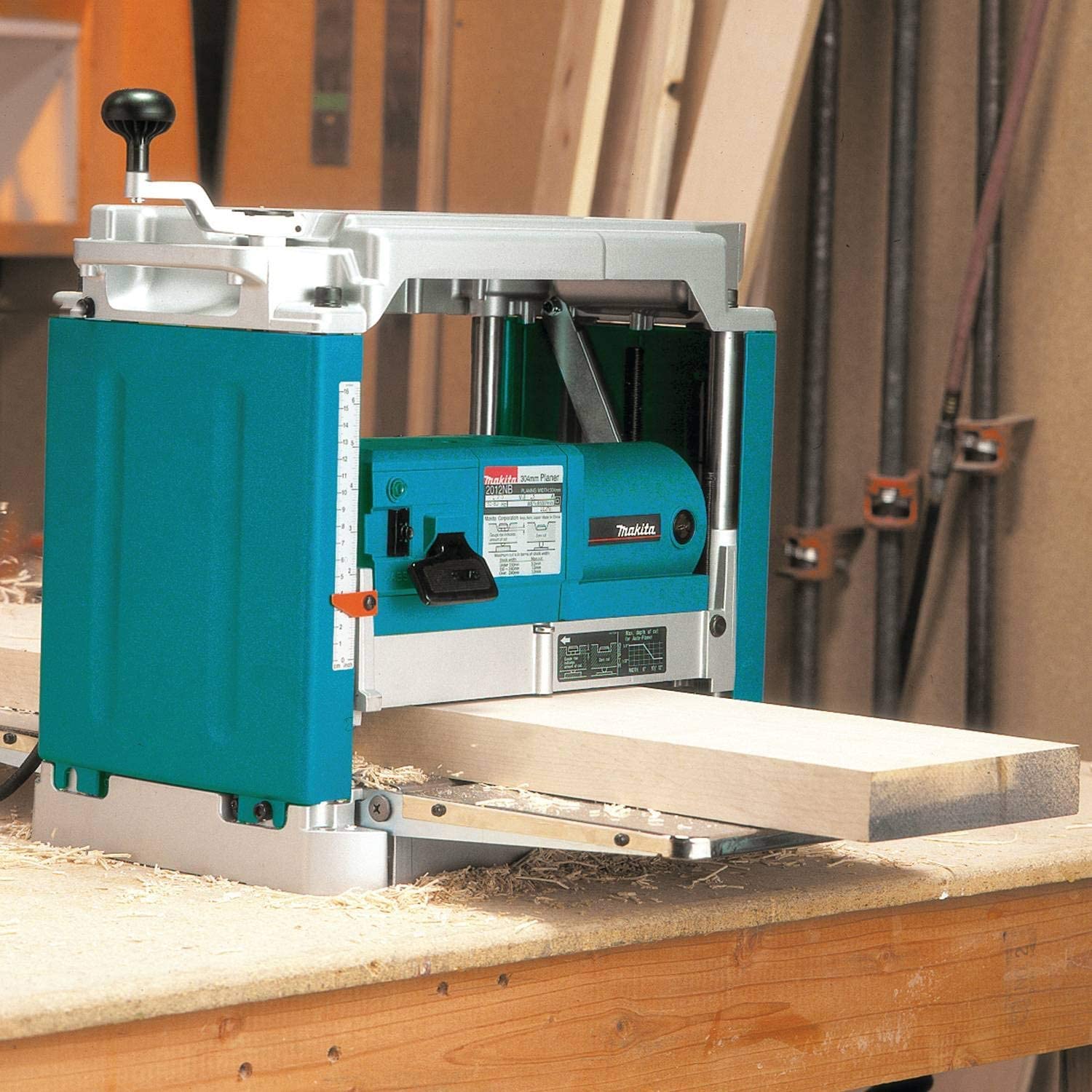

A thickness planer is a machine that planes timber down to the desired depth or thickness. Some larger models have casters and are freestanding. However, many budget-priced, DIY thickness planers are smaller and so they tend to sit on a bench.

Often people build dedicated trollies/carts for them so that they can be moved easily; this helps when planing very long planks of timber as it allows you to position the planer in such a way that it gives you enough space in the workshop to manoeuvre the wood.

They are great if you need to plane a number of workpieces down to the exact same thickness as you can set the height of the cutting blades, pass the workpieces through one by one and the blades will accurately plane each piece to the exact thickness.

How does a thickness planer work?

Thickness planers use a set of blades that are either fixed or adjustable in height, and these cut the wood as it passes through. The blades are mounted on a cutter head which spins rapidly, cutting into the wood as it does so.

The amount of board being cut is decided by how far down the blades are adjusted and this is typically adjusted using the cutter head raising and lowering wheel.

The blades on the machine are what cut down into the wood, getting rid of excess material. Depending on how deep you want to go with your cut will depend on how far you set the blade in relation to the board or plank that’s being fed through it.

What is a thickness planer used for?

Generally, a thickness planer is used when you need to cut a lot of timber or material down to a consistent thickness. They make light work of reducing the thickness of long boards, which would otherwise take much longer and be less accurate to achieve if using a hand plane instead.

Thickness planer parts

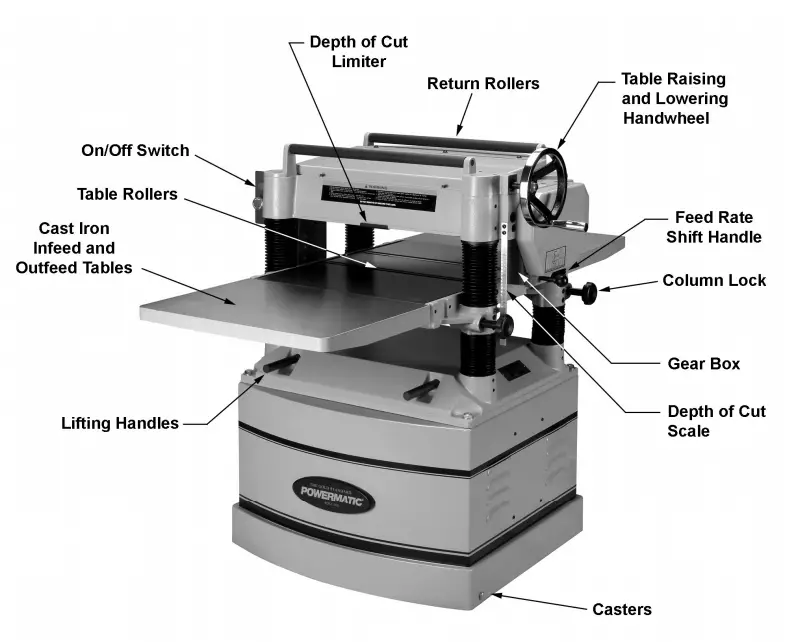

A thickness planer consists of:

- On/off switch

- Cast iron infeed and outfeed tables

- Raising and lowering wheel

- Depth of cut scale

- Dust port

- Cutter head

- Cutting knives that fit into the cutter head

The dust port is for when you are planing a lot. The blade will create sawdust and chips, so this attaches to the outside of your machine at the back and sucks away all those harmful materials.

Thickness planers have two tables – an infeed table where wood is placed before it’s feed through the blades, which removes material from both sides as well as from just one side if needed; then there’s the outfeed table that catches the timber after passing through.

How to use a thickness planer

- Firstly position the thickness planer so that there is enough clearance around it to feed the timber into and out of the machine.

- Ensure that the wood that you want to plane is sized correctly so that it will comfortably pass through the thickness planer and that you can handle it safely.

- Secondly ensure that you are wearing appropriate safety equipment, especially:

- Protective gloves

Hearing protection – Planers are very loud - Goggles or safety glasses (in case of stray wood chips)

- Dust mask (thickness planers make a lot of dust)

- Protective gloves

- Adjust the thickness planer using the wheel so that the depth-of-cut scale reaches the desired thickness.

- As a rule of thumb, for the first pass, only take off about 1-2mm of wood.

- Take lots of small passes, adjusting the depth of cut slightly each time, rather than trying to take a large thickness off in one go.

- Leave at least 4″ or approximately 100mm at each end of the board to account for snipe.

Thickness planer snipe/sniping

Thickness planer snipe is when the planer takes larger amounts of material off as it gets closer to the end of the board.

The result will be a thinner section at one or both ends of your board which will need to be discarded as it will be thinner than your desired thickness.

Thickness planer tips and tricks

Using a thickness planer can be quite intimidating as it is a very noisy and potentially aggressive machine. Therefore, here are a few tips and tricks to help you get the best out of a thickness planer:

- When cutting long lengths of timber such as boards with high grain content (the “grain” refers to the direction in

- When using a thickness planer, you need to ensure the blades are sharp and in good condition. Dull blades will not plane off as much wood from your workpiece, meaning they take longer to get it down to the desired thickness.

Thickness planers reviews

For our buyer’s guide for the best Thickness planer, please see our guide here, where we will pick out our favourite Thickness Planer for Beginners, our choice of the Best Thickness Planer and the Best Budget Thickness Planer.

Thickness planer used for sale

If you are looking for a thickness planer and cannot afford to purchase a brand new machine, then there are various places where you can find decent used thickness planers including Facebook Marketplace, eBay and local classifieds listings.

You will find models from manufacturers including Ryobi, Grizzly, Dewalt, Makita, Jet and more. However, take precautions whenever buying second hand.

Cheaper options might include buying a hand planer which will allow for smaller areas to be planed and often cost considerably less.